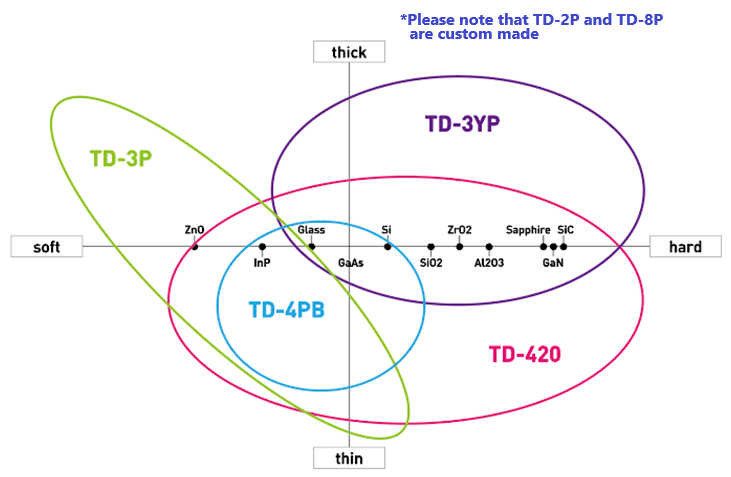

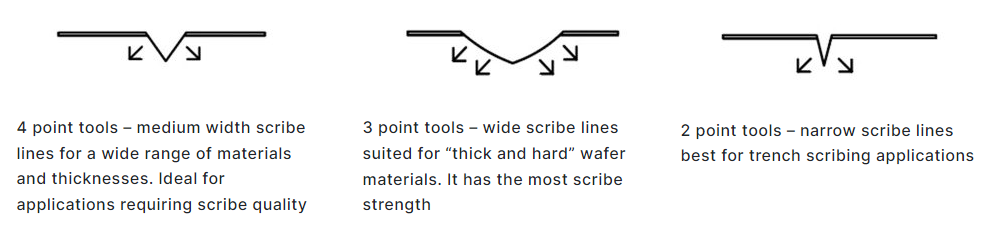

Die singulation performed with a diamond scribe and break process has distinct advantages over conventional saw or laser dicing methods. Scribe and break is inherently a dry process which generates virtually zero heat and requires no liquid coolants that can potentially damage sensitive structures. Because scribing propagates micro-cracks inside the wafer material along crystal boundaries, a cross-section facet with a mirror like surface results, free from laser ablation or dicing damage. The scribing process requires virtually no kerf hence allowing die density to be maximized. Tecdia has an extensive array of 2, 3, 4 and 8 cut-point tools that are suited for wafer thicknesses from 50-500 microns.

|

Utilize the tip of the cut point diamond for narrow and shallow scribe lines

Use a lower triangular point, creating a wider and deeper scribe line

Best in Class Tool

Each tool is meticulously crafted and inspected to only the highest standards for shank uniformity, diamond positioning and cutting angles.

High Yield Potential

Our standard shank is designed to work with most commercially available scribing platforms. Although not recommended for best performance, our tools can be used in hand scribing applications.

Design

Tecdia scribe tools are designed for longevity and maximum wafer singulation yield. Diamonds are bonded to the shank through a proprietary method that yields extremely accurate alignment geometries.

Tecdia now offers a 30 day free rental service for the part numbers TD-3YP, TD-4PB, TD-410, TD-420.

For this service all that we ask is you fill out our short survey upon the end of the rental period and return the parts to us.

For more information please contact us at sales@tecdia.com

TD-3YP

|

TD-3P

|

||

TD-4PB

|

TD-420

|

||

| * Please specify the angle. |

|

TD-2P

|

TD-8P

|

||

|

* Please contact us for specifications. |

Water-soluble materials and static electricity because water is not used during scribe

In addition, there is no adverse effect on the chip due to water.

Generally, the width of the V-groove by scribe is 2 to 5 μm, so the chip integration rate per wafer can be increased and cost reduction can be planned.

Scribe cut is to cut the chip into the desired shape by using the internal stress generated by scribe and the cracks generated from it.

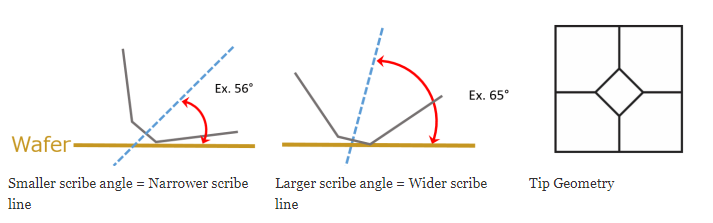

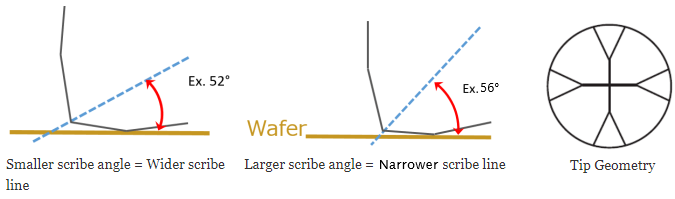

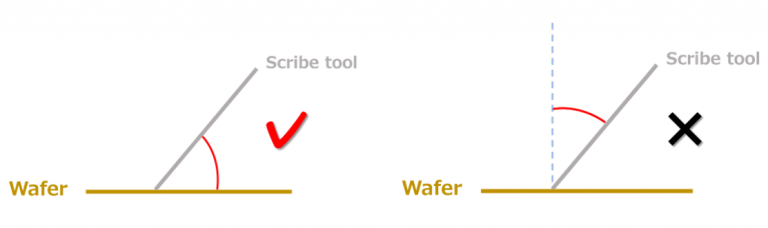

In order to control this crack well, it is necessary to select the optimum cutting edge shape for the wafer.

Scriber groove profile (TD-2P) |

Scribe cut tip cross section

Laser cut chip cross section |

Singulating Soft Wafer Material: Zinc Oxide (ZnO)

Singulating Hard Wafer Material: SiC

Increased demand for InP semiconductors due to the development of 5G

+1-408-748-0100

+1-408-748-0100

Office Hours: 8:30am - 5:30pm PST