The conventional scribe and break methods for singulation of ZnO wafers produces a low yield of acceptable die. Sawing or laser scribing are not good alternatives because the wafer material is easily damaged by high heat and coolants. This has stymied mass product production.

The customer chose Tecdia because we know scribing tool technology and scribing processes as an equipment designer and manufacturer.

We possess unique diamond craftsmanship, and we are a company that is committed to working with customers in order to find customized solutions to their manufacturing requirements. To Tecdia, the design should produce results that exceed the customer’s expectations; this is our tradition.

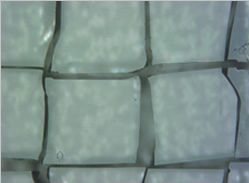

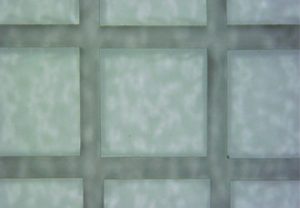

We began by selecting the “heel” type scribe tool, and developed a right geometry to ensure sharp and deep cuts allowing good internal crack to occur. Then we perfected scribing technique by using Tecdia brand scribing equipment to experiment with a rich variety of cutting methods. Using what we learned, we added a feature to our machine for selection of material cutting characteristics. In addition to being able to specify various scribing conditions like weight (stress) and speed, the result was a clean and neat separation of diced chips on the holding tape. Scribed straight down the “streets.”

Scribing Equipment

Scribing Diamond Tip

Having demonstrated that it can be done, the next phase is incorporating the new technology into the manufacturer’s production line.

When ZnO wafer manufacturers begin using our new scribing process, the prospects for new products are limitless.

+1-408-748-0100

+1-408-748-0100

Office Hours: 8:30am - 5:30pm PST