|

Philippines Facility Design Guide

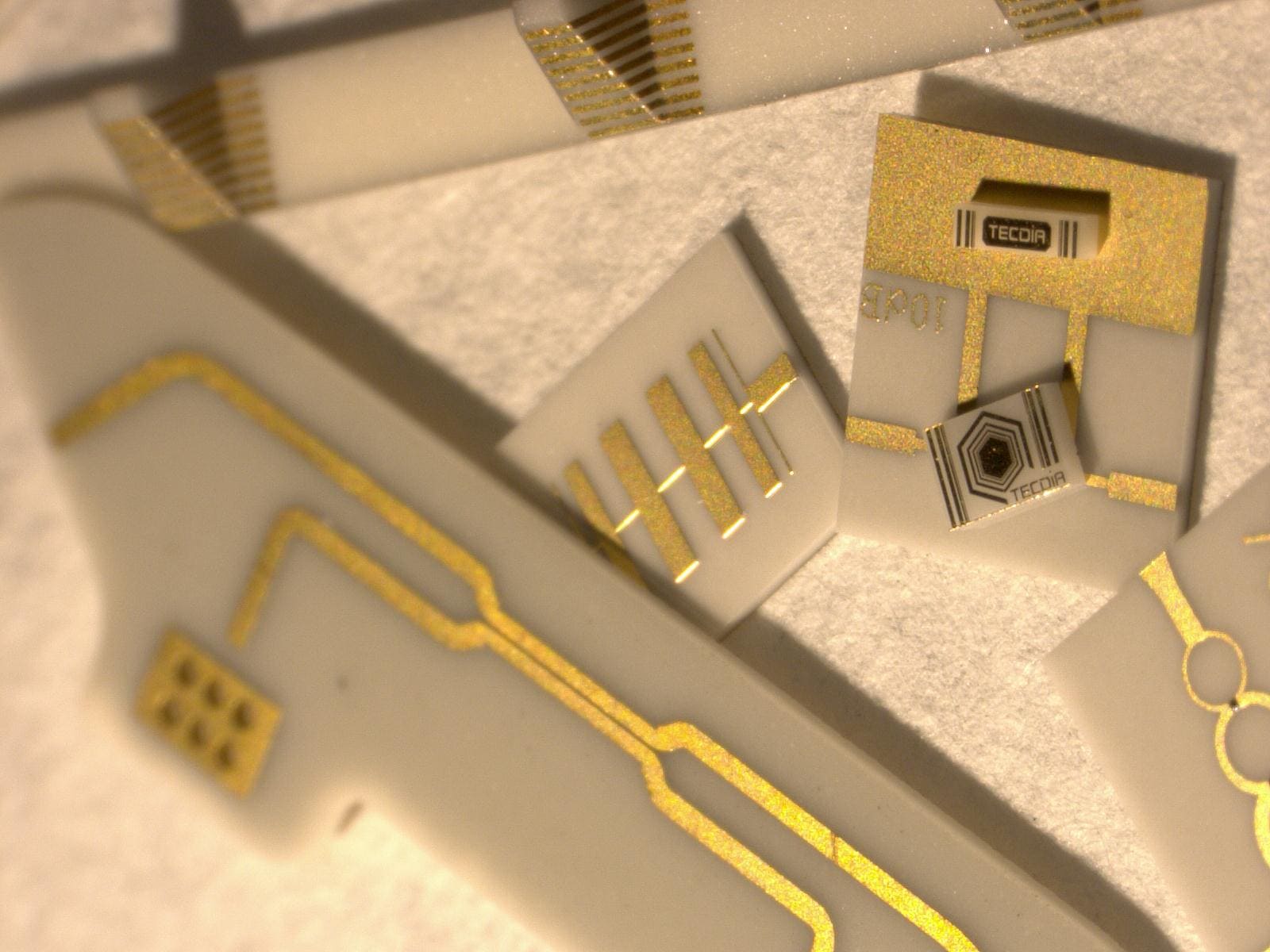

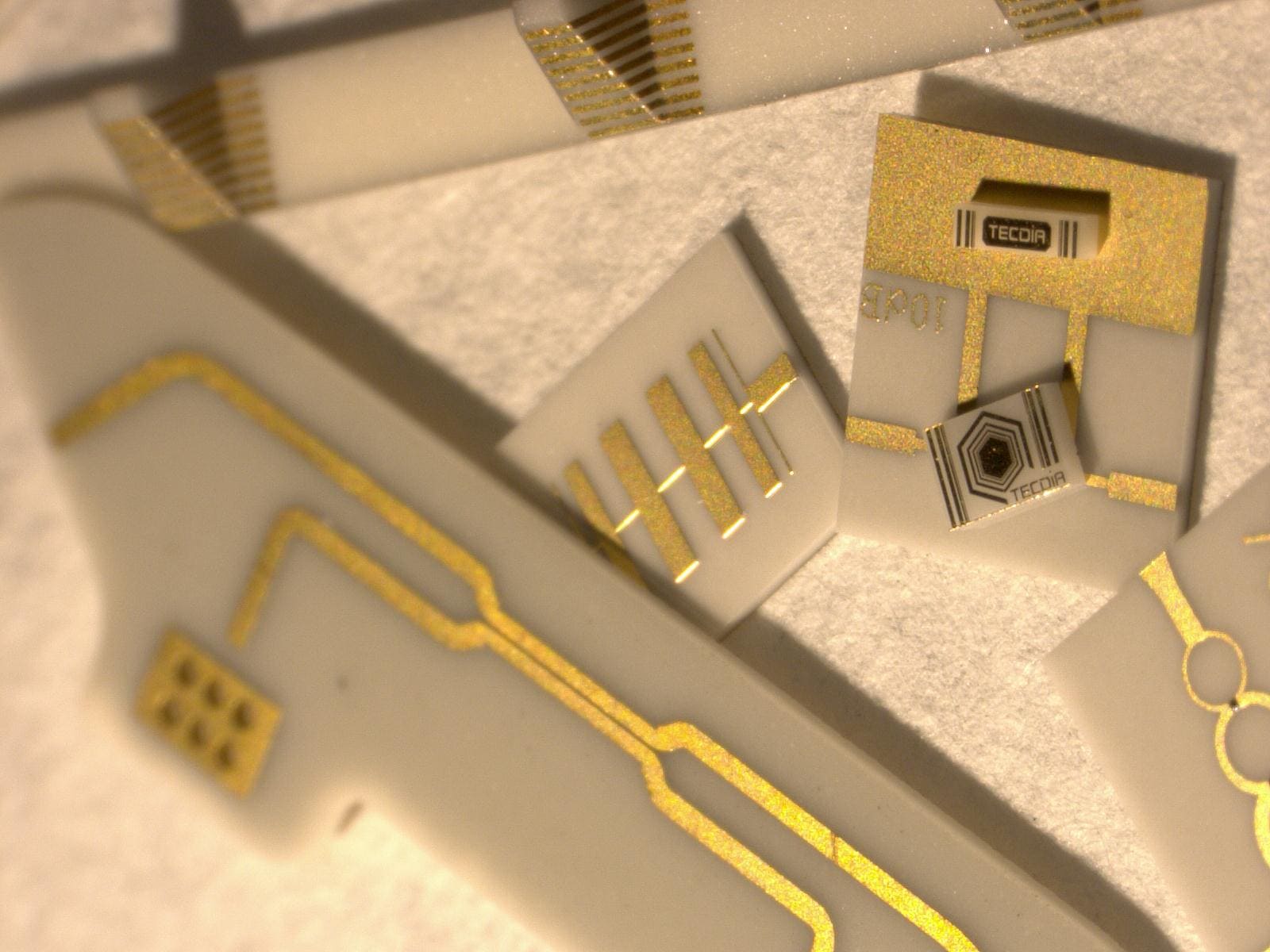

・Suitable for a wide range of applications for civil and aerospace systems.

・Inspection method grades are classified into three types: standard, commercial, and custom.

・Mechanical and electrical characteristics are inspected by sampling for each lot, and visual inspection is performed on all products.

| Inspection Item | Inspection Quantity | Allowable number of Defects | |

| Visual Inspection | Inspection Lot AQL II(1.0%) | Inspection Lot AQL II(1.0%) | |

| Dimension measurement | 3 pcs per Wafer Lot | 0 | |

Other inspections vary depending on the design, so please contact us if you have any questions.

| Item | Test Conditions | ||||||

| temperature cycle | MIL-STD-883 / Method 1010 Cond. A / B / C | ||||||

| Thermal Shock | MIL-STD-202 / Method 107 Cond. A / B / F | ||||||

| Die Shear Strength | MIL-STD-883 / Method 2019 | ||||||

| Vibration | MIL-STD-202 / Method 201 | ||||||

| High Frequency Vibration | MIL-STD-202 / Method 204 Cond. A / D | ||||||

| Variable Vibration | MIL-STD-883 / Method 2007 Cond. A | ||||||

| Unit | Alumina(Al2O3) | Aluminum Nitride(AlN) | ||

| 99.6%(Standard) | 170W/mK(Standard) | |||

| Thickness | mm | 0.254 / 0.381 / 0.508 / 0.635 (Min: 0.10 Max: 1.30) |

||

| Thickness Tolerance | mm | 0.013 | ||

| Size | Maximum | mm | 10.0 × 10.0 | |

| Minimum | mm | 0.25 × 0.25 | ||

| Surface Roughness | Surface | Ra μm (μ”) | Polish 0.025 (0.001) | Polish 0.051 (0.002) |

| Backside | Ra μm (μ”) | Polish 0.025 (0.001) | Polish 0.051 (0.002) | |

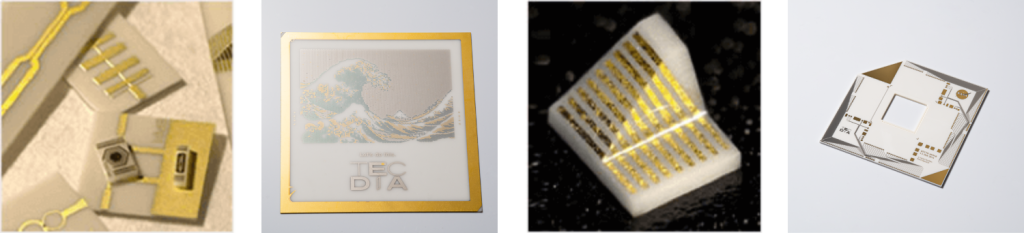

| Film Composition | Electrode Film | – | Ti – Pt – Au | |

| Film Thickness | Standard | μm | Au: 0.10 – 5.00 Pt: 0.15 Ti: 0.06 |

Au: 0.10 – 3.00 Pt: 0.15 Ti: 0.06 |

| Resistance | Resistive Film | – | Tantalum Nitride (TaN) | |

| Sheet Resistance | Ω/sq | 25 / 50 / 75 / 100 | ||

| Temperature Characteristics | ppm/℃ | -100 ± 50 | ||

| AuSn | Composition Ratio | % | Au : Sn = 80 : 20 (Nominal) | |

| Thickness | μm | 3.00 – 7.00 | ||

| Line and Space | mm | Standard 0.025 / 0.025 Minimum 0.01 / 0.01 | ||

| Set Back | mm | Standard 0.03 | ||

*Please contact us for other materials such as dielectrics, ferrite, quartz, etc.

*Please contact us for other specifications.

| Item | Unit | Specification |

| Tone | – | White |

| Content* | % | 99.6 |

| Density | g/㎝2 | 3.88 |

| Thermal Conductivity | W/m・K | 26.9 |

| Thermal Expansion Coefficient | X10-6 /℃ | 25 ~ 300℃ : 7 |

| 25 ~ 600℃ : 7.2 | ||

| Permittivity ε | @1MHz | 9.9 |

| Dielectric Loss | @1MHz | 0.0001 |

| Volume Resistance | Ω・cm | 25℃ : >1.0×1014 |

| 100℃ : >1.0×1014 | ||

| 300℃ : >1.0×1014 |

| Item | Unit | Specification |

| Tone | – | Gray |

| Density | g/㎝2 | 3.3 |

| Thermal Conductivity | W/m・K | 170 |

| Thermal Expansion Coefficient | X10-6 /℃ | 25 ~ 500℃ : 4.6 |

| Permittivity ε | @1MHz | 8.8 |

| Dielectric Loss | @1MHz | 0.0001 |

| Volume Resistance | Ω・cm | 25℃ : >1.0×1014 |

If you have a specific packing method that you would prefer to use, please let us know.

| Material | Color | Size | |

| Waffle pack | ABS | White / Natural | 2inch / 4inch |

| Waffle pack* | Anti Static | Black | 2inch / 4inch |

*Please contact us for the pocket size of the tray.

Product: European RoHS directive compliant

Packaging materials: Conforms to European directives on containers and packaging and waste containers and packaging

| Performance Guarantee Liability Period | 1 Year after Delivery | |

| Storage Conditions* | Waffle Pack | Temperature +13℃~ +33℃ Humidity 60%RH or less |

| Blue Tape(UV tape excluded) | Temperature +20℃~ +26℃ Humidity 60%RH or less | |

*Avoid storage under normal pressure, direct sunlight, vibration, impact, corrosive gas atmosphere, other special gases, freezing, condensation, and dusty environments.

Also, do not touch the product directly with bare hands.

When mounting, be careful not to short-circuit the sides due to overfilling the adhesive.

Also, cracks depend on the mounting conditions, so we recommend that you check them under your own conditions.

| ・Wire Type | less than Φ30um of Au wire |

| ・Bonding Temperature (Supplementary Matter) | Wedge Bonding: 200~270℃ Ball Bonding: 150~250℃ It is recommended to use tool heating together. |

| ・Bonding Method | Thermocompression or ultrasonic thermocompression |

| ・Notes | Bond at a distance of 25um or more from the electrode end. In addition, if the bonding acceleration is large with hard wire, the surface of the ceramic material will be damaged. it may cause electrode peeling, so we recommend checkingand adjusting according to the mounting conditions. |

Case Studies Page: NASA Chooses Tecdia for Precision TaN Circuits

+1-408-748-0100

+1-408-748-0100

Office Hours: 8:30am - 5:30pm PST