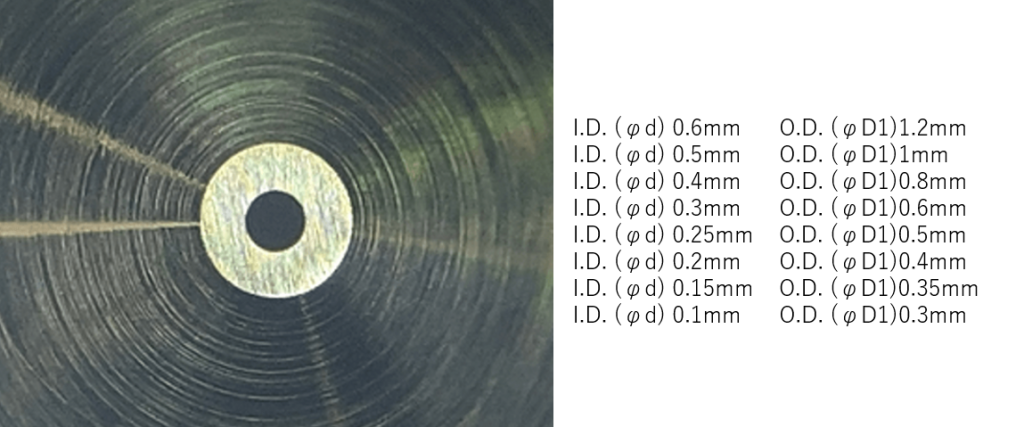

| 0.1mm | 0.15mm | 0.2mm | 0.25mm | 0.30mm | 0.40mm | 0.50mm | 0.60mm | |

| Series | ||||||||

| kaika1 | kaika110 | kaika115 | kaika120 | kaika125 | kaika130 | kaika140 | – | – |

| kaika6 | kaika610 | kaika615 | kaika620 | kaika625 | kaika630 | kaika640 | kaika650 | kaika660 |

| kaika7 | – | – | – | – | kaika730 | kaika740 | – | – |

| – | – | – | – | kaika730P | kaika740P | – | – | |

| kaika8 | kaika810 | kaika815 | kaika820 | kaika825 | kaika830 | kaika840 | kaika850 | kaika860 |

| kaika10 | kaika1010 | – | – | – | – | kaika1040 | – | – |

*Compatibility with third-party manufacturer printers has been confirmed internally though is subject to change. Tecdia doesn’t guarantee perpetual compatibility.

Nozzles combining both excellent fluidity and abrasion resistance. The nozzles have the same shape as brass kaika nozzles, but adopt a body made of tool steel that has been hardened with specially selected Japanese hardening technology.

| Hole Diameter | 0.40mm | 0.60mm |

| Series | ||

| kaikaS6 | kaikaS640 | kaikaS660 |

| kaikaS8 | kaikaS840 | kaikaS860 |

1: Seamless Filament Extrusion with an Advanced Internal Design.

Ensuring smooth filament extrusion is vital, which is why we’ve engineered the internal taper of our kaika nozzles to be free of any steps or irregularities—a feature borrowed from our acclaimed ARQUE precision dispensing nozzle series.

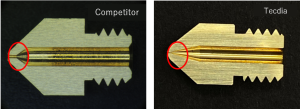

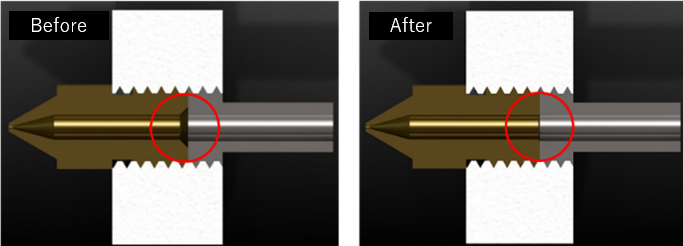

2: Eliminating Leakage and Material Buildup via Inlet Chamfer Removal.

We have eliminated unnecessary gaps between the nozzle and remainder of the hot end, effectively preventing material accumulation and blockage.

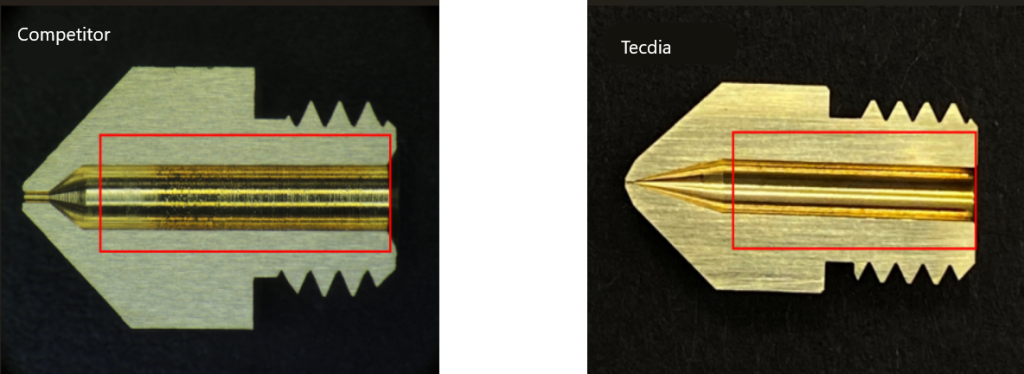

3: Achieve Precise Printing with Reduced Inner Surface Roughness.

Through our unique processing technique, we meticulously polish any scratches or irregularities that may occur during the nozzle’s internal manufacturing. This results in a smoother surface, enhancing material flow and enabling precise and consistent printing.

4: Optimized Outer Diameter for Both Priming and Fine Detail Coating.

We have precisely set the end face area of the difference between the inner and outer diameters of the nozzle tip to its optimal value. This innovative design allows for precise extrusion in fine details and facilitates efficient ironing.

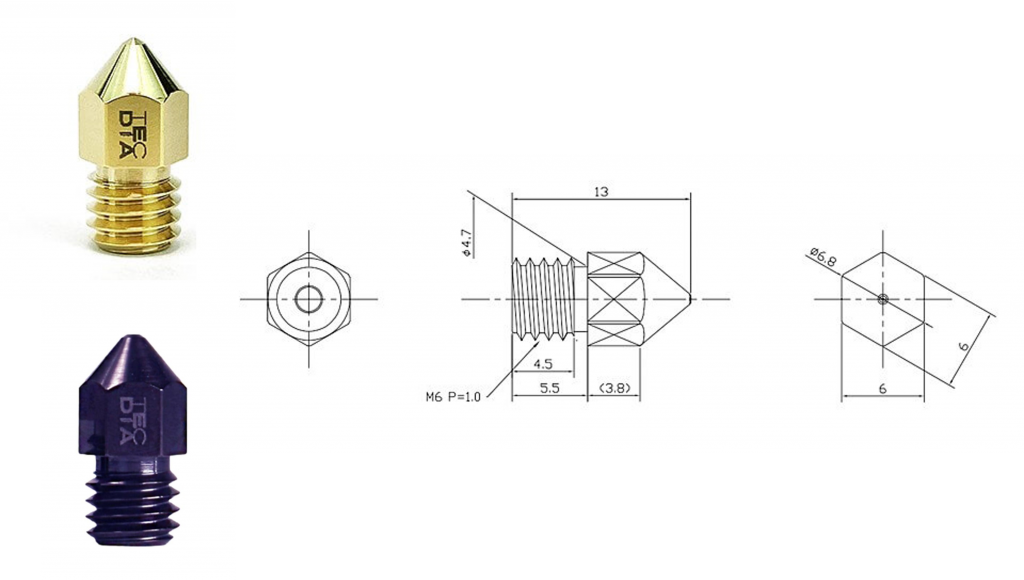

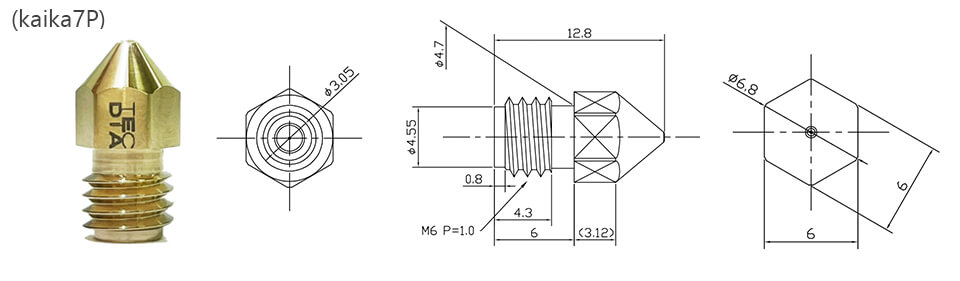

Featuring a precise 30-degree sharp internal taper angle. Additionally, we’ve extended the standard 60-degree outer diameter slope to an impressive 120 degrees, resulting in superior cushioning, smoother tip impact, and optimal heat capacity. Generally used on printers like Prusa.

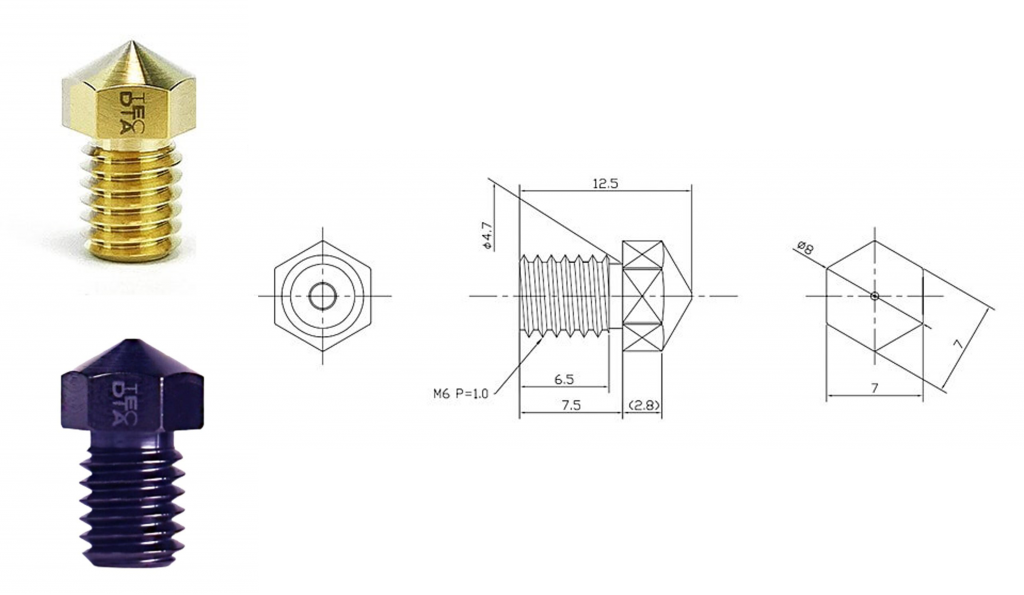

Featuring a two-stage taper design with an 80-degree outer diameter slope and a sharp 120-degree tip. This unique configuration enhances cushioning during tip impact, ensures a smoother operation, and guarantees ample heat capacity. Generally used on printers like Ender.

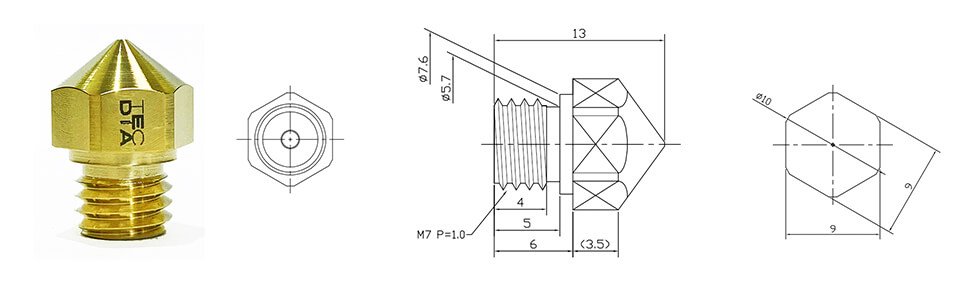

Our exclusive nozzle design eliminates the need for Teflon tubing, ensuring optimal filament melting. Generally used on printers like Flash Forge.

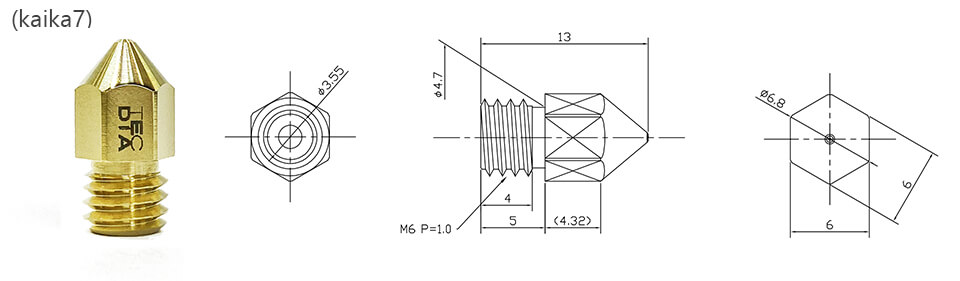

Experience versatility with Series 7, offering two distinct threading options. Choose the one that perfectly matches your equipment for seamless integration. Generally used on printers like Zortrax.

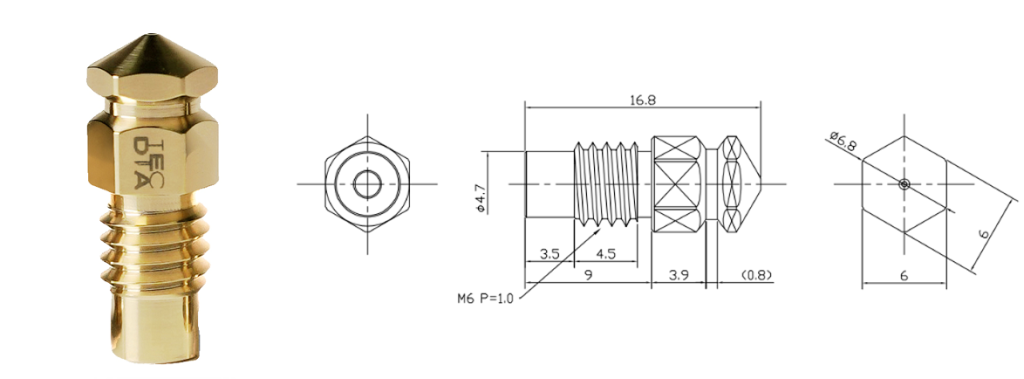

A large head with an outer diameter slope of 120 degrees, offering excellent heat retention capability. Shortening the threaded section reduces the risk of thread loosening and damage due to vibrations during printing. Generally used on printers like Ender-5 S1.

You can purchase the precision 3D printer nozzle (kaika) from the official online shop listed below.

Case Study: Development of Tecdia’s Original 3D Printer Precision Nozzle “Kaika”

+1-408-748-0100

+1-408-748-0100

Office Hours: 8:30am - 5:30pm PST