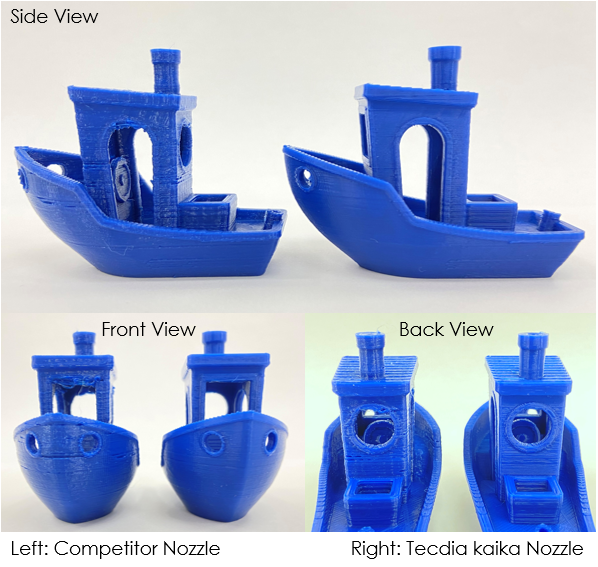

Despite the desire for pristine prints, achieving the desired results has been a challenge.

3D printer users, who strive for precision in creating figures, smartphone covers, drone parts, and other objects, have voiced various concerns. These include challenges with achieving precise detailing due to resin not coming out vertically from the nozzle, resin leakage from the base of the nozzle, stringing issues where the nozzle drags filament while moving (also known as “stringing”), and resin drooping in bridging areas. These challenges have led to a search for solutions. Many of the users facing these concerns either utilize the default nozzles provided with their 3D printers or opt for lower-cost nozzles ranging from 100 to 400 yen when replacing the nozzle.

Introducing kaika, the Precision Nozzle for 3D Printers – Achieve Easy and Pristine Printing

Tecdia has a track record of adopting its nozzles in the semiconductor and regenerative medicine industries, recognizing that nozzle quality is the key to achieving printing precision. Thus, we developed the precision 3D printer nozzle “kaika” based on feedback from 3D printer users and leveraging our in-house metal processing expertise. The distinctive features of the “kaika” nozzle, infused with our unique nozzle technology, are as follows:

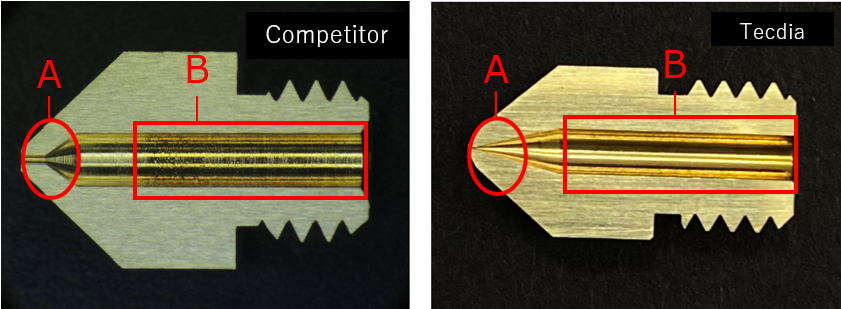

①Interior

By eliminating the step in the tip section (Figure A), resistance is reduced, enabling smooth extrusion of the resin. Additionally, polishing the inner surface (Figure B) results in a smoother surface, reducing friction between the resin and the nozzle. This minimizes clogging and ensures stable and pristine printing.

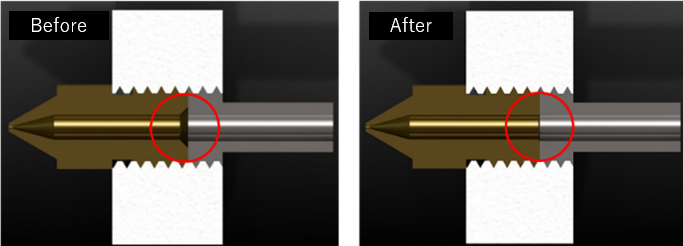

②Gap between the printer and the nozzle.

With an original design that eliminates gaps between the printer and the nozzle, it prevents resin leakage and accumulation.

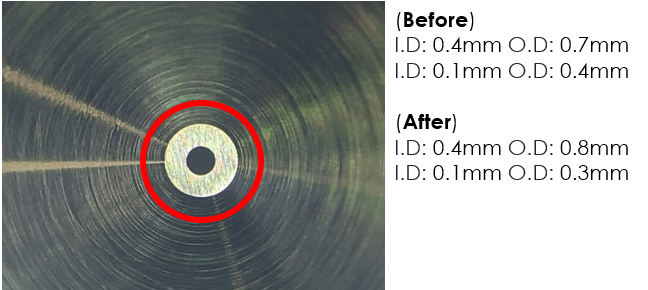

③Nozzle tip

By adjusting the end face area for 3D printing, it achieves an optimal shape for both precise extrusion and priming. Additionally, the concentric design of the nozzle from the end to the tip allows resin to flow vertically, reducing noticeable layer lines.

Printing Precision is Determined by the Nozzle!

Even with an inexpensive 3D printer, simply attaching a good nozzle can yield results beyond the device’s price. Similar to the relationship between marathon runners and shoes, or cars and tires, the selection of the right tool is crucial. No matter how much practice one puts in, without the best equipment, achieving optimal performance becomes difficult. Therefore, Tecdia believes that in 3D printing, it is important to emphasize the significance of the “nozzle”.

Users have expressed great satisfaction with the ability to achieve intricate detailing close to photopolymerization (SLA) technology. The extended lifespan and reduced issues of nozzle wear and clogging have also resulted in increased user satisfaction, cutting down on replacement efforts and costs. Going forward, we plan to expand our product lineup and offer more variations in nozzle types to meet evolving needs.

–

+1-408-748-0100

+1-408-748-0100

Office Hours: 8:30am - 5:30pm PST