Creating a dispenser nozzle to achieve accurate and stable application

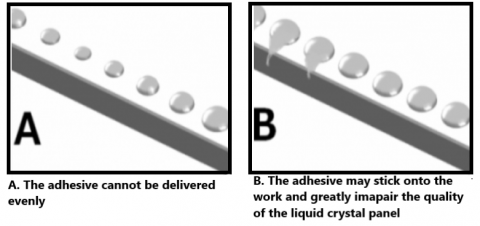

Adhesion of liquid crystal display panels plays an important role due to the accuracy of adhesive application is directly related to touch panel performance. It was necessary to make various improvements such as fixing creep up on the tip of the nozzle when applying adhesive, as well as fixing the clogging of the material inside the nozzle.

Developed a nozzle with a Ruby tip.

Tecdia has developed a dispenser nozzle with a ruby tip. The tip of a normal dispenser nozzle is made of stainless steel, but we have succeeded in improving internal fluidity by using ruby, which has less wear. In addition, it suppresses the common issues such as material clogging and dripping, while realizing accurate and stable application. Due to the toughness of the ruby, the tip wear caused by contact with the glass substrate was also reduced, leading to a shorter takt time.

Significantly improved coating accuracy by applying unique tip lapping.

In addition to adopting the ruby tip, we have adopted a “tip wrap” which is also a feature of the Tecdia dispenser nozzle. It polishes the flat surface of the nozzle tip, suppressing the surface tension with the material and greatly reducing the dispersion of application due to creeping up and liquid pool. This product also supports custom manufacturing and the tip inner diameter can also be selected according to the customer’s application, which was also the deciding factor for the introduction of *0.05mm ~ φ0.50mm size.

Accurate and stable application contributes to higher definition and thinner LCD panels. Please feel free to contact us if you have a problem with your current dispenser nozzle or if you are pursuing more accurate dispensing. As an expert in dispenser nozzles, we will propose the most suitable dispenser nozzle for your application.

[Client industry] LCD panel manufacturer (Taiwan)

[Business description] LCD panel manufacturing

+1-408-748-0100

+1-408-748-0100

Office Hours: 8:30am - 5:30pm PST