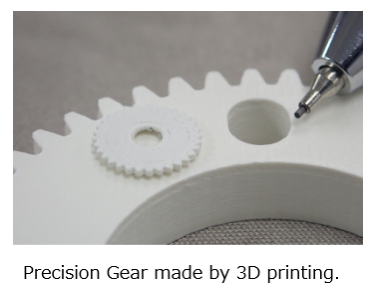

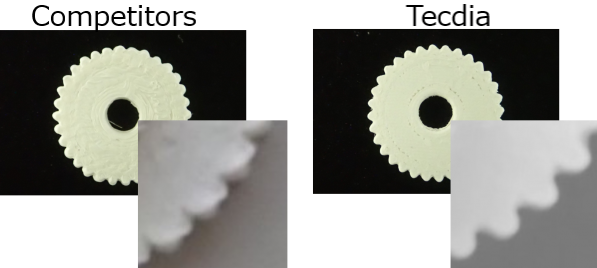

Otsuka Chemical Co., Ltd., a major chemical manufacturer, develops precision parts such as gears and bearings by 3D printing using its own composite material “Poticon”. 3D printing using Poticon has excellent wear resistance, surface smoothness, dimensional accuracy, and more. This has been applied to automotive parts, watch parts, robot parts and smartphone camera parts. When developing precision gears using Poticon, the company could not achieve the tooth precision required by normal 3D printing alone, and after finishing the 3D printing, they would hand file the edges. Due to this, Tecdia searched for a way to make this process better.

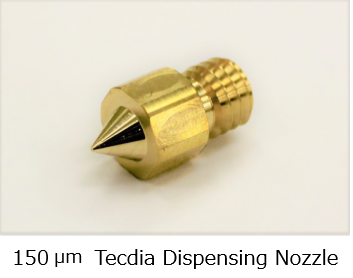

In a 3D printer, a dispenser nozzle is used for the tip part called the head, that serves as a material discharge port. The smaller the inside diameter of the tip the more elaborate printing is possible. The biggest issue in this is material clogging. The smallest inside diameter in the industry is 200 μm. Otsuka Chemical’s “Poticon” has small particles thus the possibility of clogging is decreased. This made 3D printing possible even with conventional dispenser nozzles with an inner diameter tip of less than 200 μm. We proposed the use of a dispenser nozzle with a inner diameter tip of 150 μm. Tecdia collaborated with Otsuka Chemicals and as a result of the evaluation, hand filing after 3D printing was no longer necessary.

As a specialist in dispenser nozzles, Tecdia has been customizing and manufacturing various coating materials and application conditions for dispenser nozzles. This time, we used brass with high thermal conductivity for the dispenser nozzle and customized it with the material suitable for the application. In addition, we succeeded in developing a 3D printer head nozzle for precision gears by applying a small diameter hole with high roundness without center deviation, which is a feature of Tecdia’s dispenser nozzle, and applying a tapered shape with no step inside.

By switching to Tecdia’s dispenser nozzle, we succeeded in manufacturing precision gears that were required only in the 3D printing process, eliminating the need for a file process. In pursuit of further accuracy, we have proposed and evaluated dispenser nozzles with a tip inner diameter of 100 μm.

The tip inner diameter is 150 μm this time, but Tecdia’s dispenser nozzles, which are good at drilling small diameter holes, are available up to a minimum inner diameter of 30 μm. They are also used in the regenerative medicine industry where importance is placed on accuracy and quality, such as biomaterial printing. If you are worried about printing fine shapes with a 3D printer, please contact Tecdia. As an expert in dispenser nozzles, we provide solutions unique to Tecdia, tailored to materials and applications.

+1-408-748-0100

+1-408-748-0100

Office Hours: 8:30am - 5:30pm PST