Printing Human Organs with High Precision

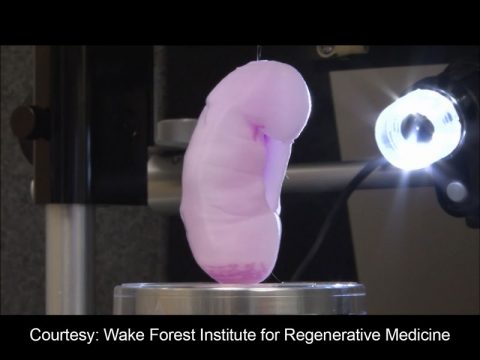

One method of 3D printing organs is to create supporting structures with polymer biomaterials, layering host cells from the bottom up. Accuracy, temperature and speed are critical for this process.

A high printing resolution of the supporting structure is necessary so complex features of organs can be recreated. The temperature of biomaterials needs to be controlled and maintained and host cells have to be placed quickly to remain protected and promote development and regrowth. Our customers were in search of solutions that enable this technology.

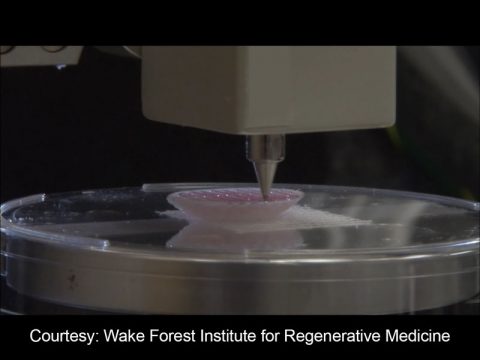

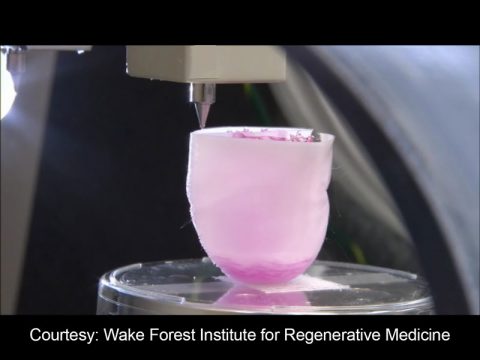

Organ printing process (kidney)

10 Micron Dispensing Nozzles, High Pressure Pump with Suck-back Function and Advanced Heating System

Using precision engineering and machining, Tecdia developed a stainless steel dispensing nozzle with an I.D. of only 10 microns.

ARQUE Premium 10µm Nozzle Tip

Attached to the print head, the 10 micron nozzle made it possible to print in high resolution and also gave way to 2 new innovations.

1) High Pressure Pump with Suck-back Function

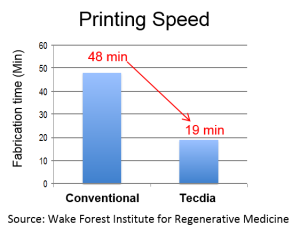

Tecdia developed a high pressure pump which reduced the printing time by 60% and also eliminates drips and line crossover during printing. This saves time, eliminates waste and reduces cell necrosis.

Printing Speed Improvement*

*When printing cubic structure (6x6x2mm)

2) Advanced Heating System

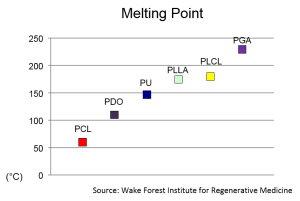

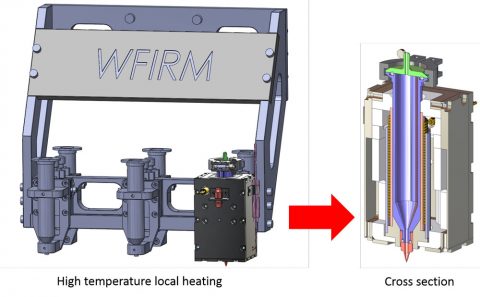

To provide the printing system flexibility with a wide variety of biomaterials, a precision heating system was needed to provide up to 300°C of localized heating. Typical heating systems were limited to only 100°C which reduced biomaterial selection.

Biomaterial Melting Points

Biomaterial Melting Points  Advanced Heating System

Advanced Heating System

3) Vacuum mechanism

Developed a vacuum mechanism for more precise printing. It suppresses printing defects such as dripping and stringing.

Ability to provide solutions by fusing two different technologies

Advanced cutting technology that can produce printing nozzles with a tip of 10 µm and system development technology suitable for biomaterial printing.

We were able to combine two different technologies and provide a solution that exceeded the requirements of our customers.

Smart solutions from Tecdia enable technology crucial for 3D printing research

[Client Industries]

Wake Forest Institute for Regenerative Medicine

+1-408-748-0100

+1-408-748-0100

Office Hours: 8:30am - 5:30pm PST