Creating a mounting method that eliminates the handling issues surrounding AuSn preforms, the current alternative to epoxy resin.

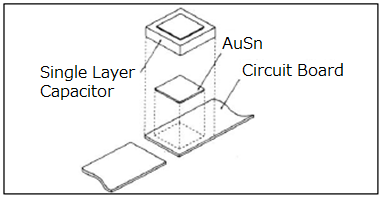

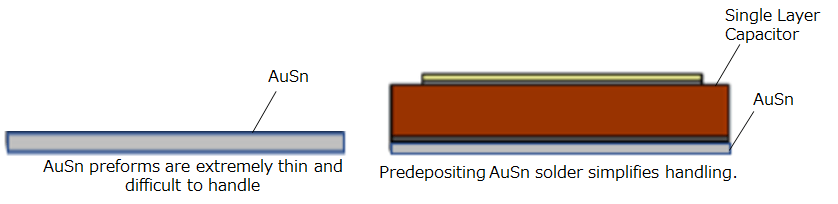

Conventional die-attach using AuSn solder requires a plate-like preform of AuSn solder to be positions between the single layer ceramic capacitor and the circuit board instead of dispensing epoxy resin. However, because the AuSn preform is very small and ultra-thin, it is difficult to handle and gives rise to the risk of shorting due to misalignment in installation position.

Development of a “ceramic capacitor with predeposited AuSn” product.

Tecdia developed a metal deposition technique to realize “ceramic capacitors with predeposited AuSn” in which AuSn solder is deposited to the backside of the capacitor at the wafer level. This eliminates the need for discrete AuSn solder preforms to be purchased or handled, improving yields and simplifying the die-attach process.

In addition to solving the handling issues, “ceramic capacitors with predeposited AuSn” contribute to a reduction in cost as the number of parts required for mounting decreases. Moreover, this leads to a reduction in manufacturing processes and effectively shortens product lead time. Although the conventionally used AuSn preforms are 20 to 30 μm thick, our “ceramic capacitor with predeposited AuSn” have an AuSn solder layer that is 10um thick. This reduces restrictions on installation locations and mounting in narrow places becomes possible due to the reduced solder spillage.

Consultation based on the motto “Let’s do this”

The company motto “Let’s do this” is to be a manufacturing proposal business. Listening to customers’ issues and aiming to solve them rather than simply selling products led to the realization of the “Ceramic Capacitor with AuSn”. In this way, Tecdia believes that it is not just a manufacturing company that follows blueprints, but rather aims to solve customer problems.

We have succeeded in creating a component that reduces product lead times by reducing die-attach costs and simplifying manufacturing processes.

[Client Industries]

Wireless communication device manufacturers

+1-408-748-0100

+1-408-748-0100

Office Hours: 8:30am - 5:30pm PST