With the spread of 5G, the speed at which communication takes place is on the rise, and with it the amount of heat generated by high-speed processing data is also increasing.

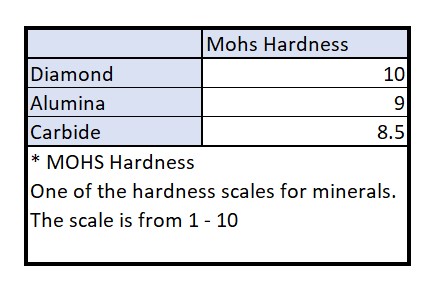

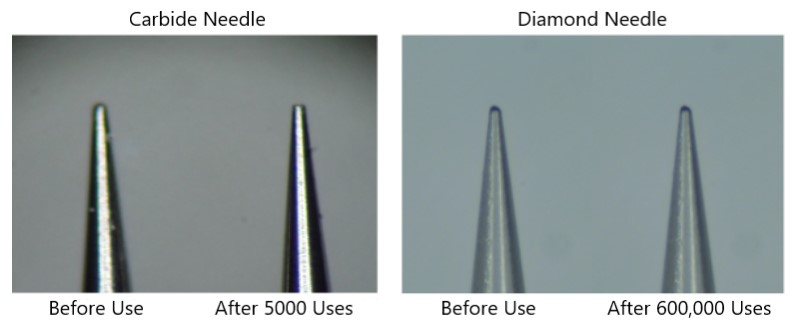

As such, semiconductor substrates are required to have high heat dissipation and high isolation. For this reason, alumina substrates have attracted attention instead of conventional organic substrates. However, since alumina (aluminum oxide) has the second highest hardness after diamond, the tips of push-up needles made of carbide used in the past result in rapid tip wear, making cost and time spent making replacements an issue for customers.

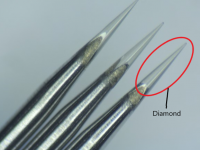

Tecdia proposed a “Diamond Needle” product, which uses diamond at the tip of the needle.

According to our customer’s evaluation, the conventional product required replacement of the needle after about 5,000 push-ups, but with the diamond needle, the needle tip maintains the same shape even after 600,000 uses.

| Cost Comparison (Taiwan S Company) | |||

| Needle Usage Per Year | Unit Price (USD) | Annual Cost (USD) | |

| Carbide Needle (Manufactured by another company) | 792 | $ 2.26 | $ 1,786.94 |

| Diamond Needle ( manufactured by Tecdia ) | 1 | $ 226.00 | $ 226.00 |

Tecdia’s strength lies in its “composite technology” in which electronic parts, precision machined products, and industrial diamond products are manufactured under one roof.

By using the combined technology, we were able to catch the customer’s consumables issue. We have a long-term relationship within the electronic parts business, and proposed a product called “Diamond Tipped Ejector Needle” as a solution.

By switching to diamond needles, annual needle usage has been reduced from 792 to one.

We succeeded in reducing not only consumables costs but also labor costs for replacement and shortening of tact time, satisfying our customers.

Semiconductor manufacturers

+1-408-748-0100

+1-408-748-0100

Office Hours: 8:30am - 5:30pm PST