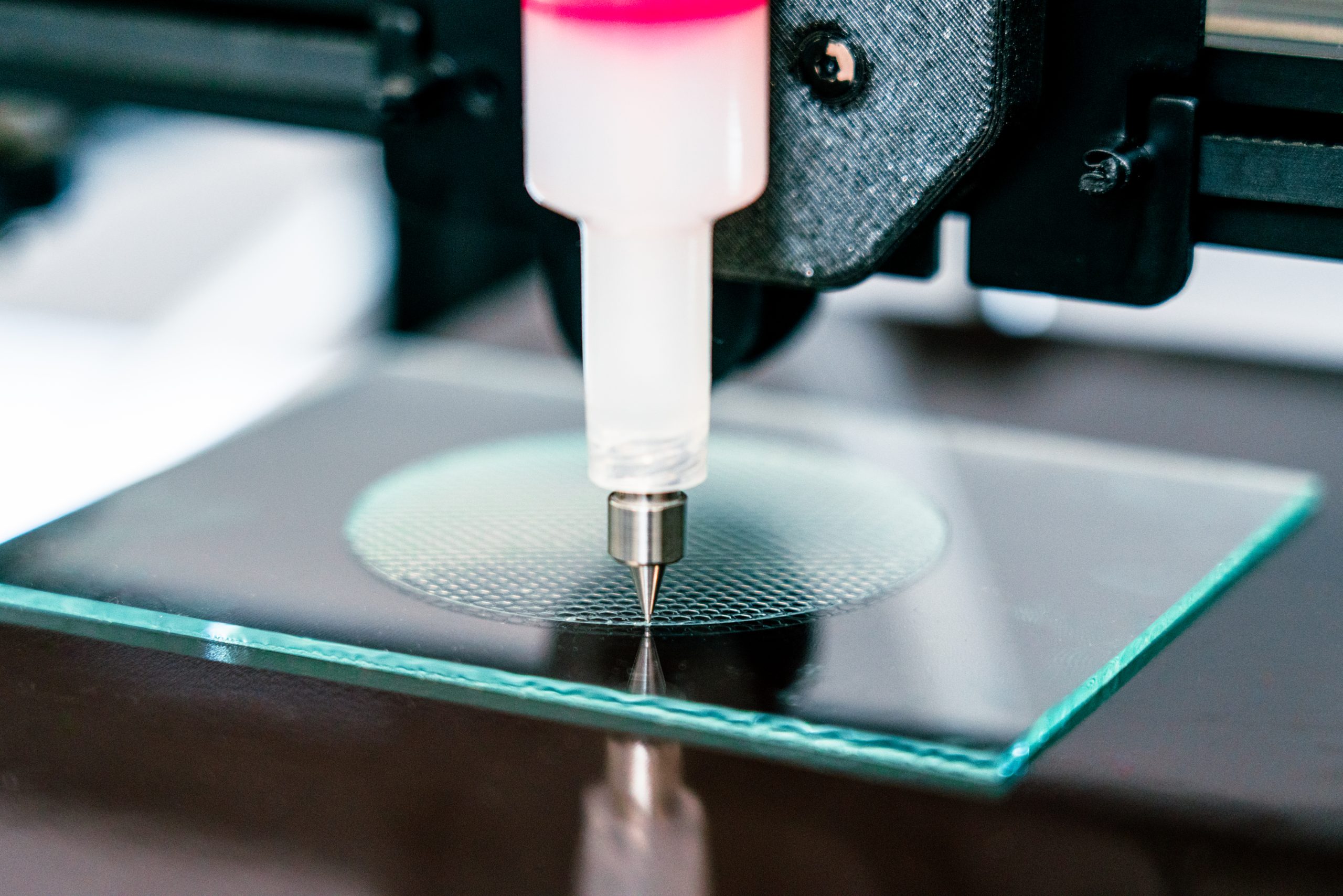

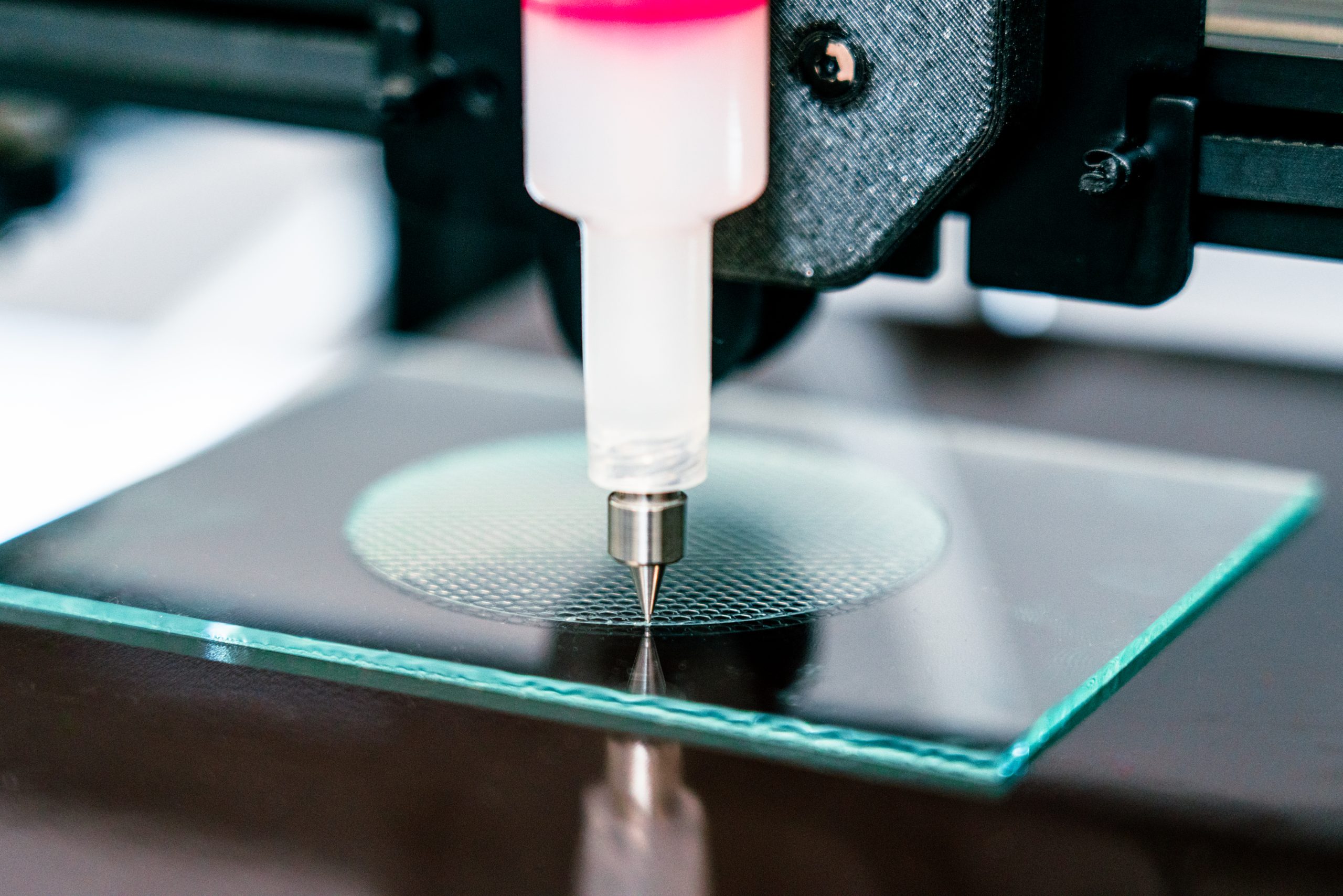

When 3D printing organic substances, so-called bioprinting, one thing must not happen: The cells in the substances to be printed must not get damaged.

Print heads from Puredyne® already achieve this today through demonstrably high-precision and low-shear dispensing. Nevertheless, the printing results are always dependent on the dispensing needle used, of which there are many available on the market.

Reason enough for Puredyne® – brand of the established dispensing specialist ViscoTec – to put dispensing needles at the top of the agenda in order to further support the growing application area of bioprinting and to find potential for innovation.

Recently, the engineers succeeded in further improving one of the most difficult parameters in 3D printing of biomaterials during in-house laboratory tests: Reproducibility.

In combination with the precision of the print head, this is an important aspect for research and development in many industries, as well as for machine and plant construction. The aim of the test series was to find out which technical possibilities exist to achieve the precise dispensing of cellular bio-substances with a focus on extreme sensitivity in a more reproducible way and to achieve the finest start and end points.

The Puredyne® print head and precision dispensing needles from the Japanese manufacturer Tecdia were used.

The print head has an integrated compressed air supply and is mounted on a bioprinter via a bayonet fitting with the single-use cartridge. Controlled by a stepper motor, the progressive cavity technology installed in the cartridge enables process-reliable and precise dispensing.

The dispensing needle, which is connected to the print head via luer lock, offers great potential for improving print quality: Experiments had shown that the risk of shearing of cells in the biomaterial is greatest in the dispensing needle. However, it is imperative that these cellular structures are protected. Although printing microscopically fine 3D objects is de facto not a big problem today, printing living cells reproducibly via extrusion is. In addition, the dispensing process must not only be precise but also fast in order to protect the cells.

Accordingly, the engineers outlined the task for the test series: The task was to find a dispensing needle that optimally complements the Puredyne® print head with its positive characteristics in precision and versatility.

During the tests, the developers found that the “Arque” dispensing tip from the manufacturer Tecdia delivered the best results and, in combination with the Puredyne® kit b, dispenses the biomaterial with the highest reproducibility. The print head equipped with an Arque dispensing needle ensures consistent line width and sharp contours throughout the entire printing process. The optimal pressure reduction also guarantees fine start and end points. According to the manufacturer, Arque dispensing tips have a seamless inner cone, which improves the flow behavior in the tip.

+1-408-748-0100

+1-408-748-0100

Office Hours: 8:30am - 5:30pm PST