Reduction of man-hours for manufacturing semiconductor devices.

Competing Manufacturers are making great strides in developing components to match this increasingly sophisticated optical communication systems. The current themes of modifications to components are in miniaturization, power saving and cost saving. Above all, the reduction of the number of parts and manufacturing man-hours, which leads to cost reduction, was urgently needed because of the increase in production due to the expansion of demand.

Providing multi-electrode capacitors

Multi-electrode capacitors are connectors that use single-layer ceramic capacitors that utilize narrow spaces during mounting and reduce manufacturing man-hours

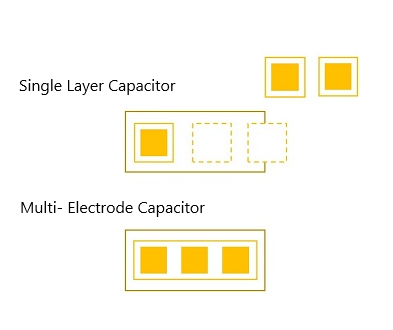

▲ Left: Single-layer ceramic capacitors Right: Multi-electrode capacitors

Single-layer ceramic capacitors are used as components of semiconductor devices. By arranging and using multiple single-layer ceramic capacitors at the same time, it is possible to utilize the narrow space at the time of design, which leads to the miniaturization of the device and the reduction of mounting man-hours.

▲ multi-electrode capacitor that enables utilization of narrow space

Customize up to 7 connections

At Tecdia, we customize and manufacture products according to customer needs, such as two-row design or a combination of capacitors with different capacitance values, and sizes.

▲ Left: 2-row design Right: Combination of different capacity values.

In general, multi-connection products are limited to 3 connections due to the risk of warping and cracking, but Tecdia can handle up to 7 connections. We will propose the optimum solution after confirming the customer’s application.

▲ Up to 7 connections can be manufactured.

By providing a row capacitor, we have contributed to the reduction of manufacturing time for semiconductor devices and reduction in cost. Tecdia has a lineup of various single layer ceramic capacitors such as rectangular capacitors and high-dielectric-constant capacitors that can be customized. We will continue to support the ever-evolving communication technology with ceramic applied technology.

–

+1-408-748-0100

+1-408-748-0100

Office Hours: 8:30am - 5:30pm PST