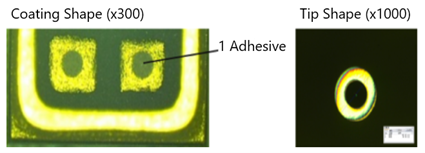

Fine adhesive application of φ100-150 μm

Fine application of adhesive is required to assemble Crystal Quartz Oscillators that are decreasing in size. ThreeBond Co.,Ltd., a major material manufacturer, develops and sells conductive adhesives for liquid crystal devices. For the manufacture of Crystal Quartz Oscillators, we have developed a unique adhesive “TB3304J” that keeps the size of the filler to 10 μm or less while maintaining the adhesive strength. A high-performance coating device and a highly accurate dispenser nozzle were required for fine coating of TB3304J at φ100 to 150 μm.

Collaboration by three companies specializing in adhesives, coating equipment, and dispenser nozzles

ThreeBond Co. Ltd. conducted a coating test aiming at coating diameters of 100 μm and 80 μm. This was done with a dispenser nozzle that had an inner diameter of 50 μm / outer diameter of 80 μm made by Tecdia and a coating device of PFA Co.,Ltd.. We succeeded in a high-precision coating test with 3σ = 8-12 μm.

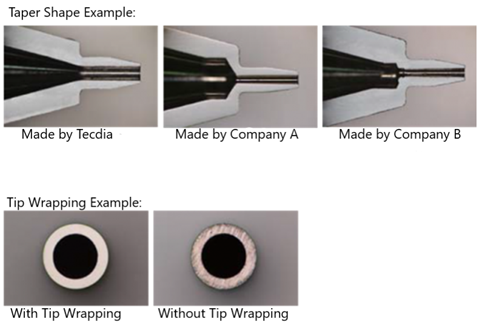

The Tecdia dispenser nozzle has a unique “tapered shape” and “tip wrapping” to prevent clogging and stringing inside the nozzle.

Tecdia’s unique “taper shape” and “tip wrapping”

The following three points are important when applying adhesive to Crystal Quartz Oscillators.

1. The dispenser nozzle is not clogged (discharging property)

2. The optimum coating diameter is achieved (coating property)

3. The shape can be maintained after coating (shape maintenance characteristics)

Tecdia uses a “tapered shape” that eliminates the step inside the nozzle to the utmost limit to prevent clogging. Furthermore, by applying “tip wrapping” that polishes the tip of the nozzle, it prevents the coating agent from creeping up and stringing, and even with a small diameter nozzle with an inner diameter of 50 μm, stable coating is achieved with no variation in coating.

Tecdia is recommended as a nozzle supplier by ThreeBond Co., Ltd. for fine coating of adhesives. Tecdia has a lineup of dispenser nozzles with a minimum tip diameter of 30 μm and can be customized. We will continue to develop dispenser nozzles that meet the needs of our customers.

+1-408-748-0100

+1-408-748-0100

Office Hours: 8:30am - 5:30pm PST