To shorten manufacturing/assembly times of semiconductor devices for fast lead times.

Fast manufacturing speed is essential to support changes in the market. Efforts to reduce manufacturing time are ongoing across the board, but a significant challenge remains with lead times associated with procurement and delivery docket date management of many electronic parts before assembly processes can even be started.

Bring the added-value service of “assembly” for electronic components.

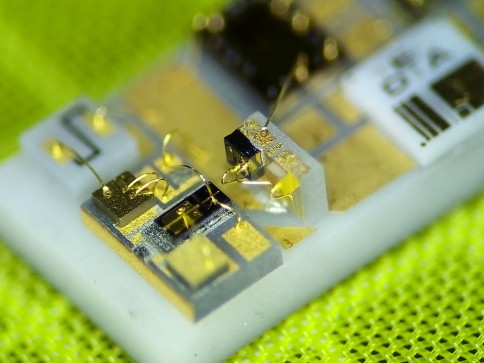

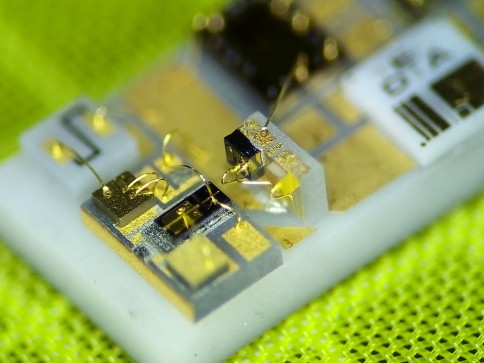

We propose to our customers to have various electronic components made by Tecdia pre-assembled using our in-house assembly processes. This means Tecdia can mount single layer ceramic capacitors and thin film chip resistors, core components of semiconductor products, in advance and prior to shipment. Delivering products in a semi-assembled state reduces time required for customer preparation and production. In addition, through customer consultation and component consignment, it is possible for Tecdia to mount electronic components from other manufacturers for delivery of complete sub-assemblies.

Tecdia’s core business is manufacturing various electronic part’s such as single layer substrate capacitors and thin film substrates.

On the other hand, our Cebu factory has a proven track record of providing OEMs of optical communication semiconductor devices and microwave communication semiconductor devices with assembly solutions since the 1990s. Combining our experiences and assembly expertise, such as those with FETs and optical transceiver modules (TOSA, ROSA, BOSA), we have emerged as a one-stop shop for component manufacturing through to assembly.

We also have a precision machining division for the creation of any kind of jig we need to improve process capability and tact time using our in-house CNC lathes, mills and other machinery. Moreover, we have a network of material vendors that enable us to assist with procurement. Our unique solutions have been proven to lead to significant reductions in production time for our customers.

We are able to swiftly support various assembly scales from high-mix low-volume prototype builds through to mass production.

Doing this we have shortened customer product production time and contributed to the expansion of their sales channels.

[Client Industries]

Semiconductor product manufacturers

[Target Application]

Optical and microwave communication devices.

+1-408-748-0100

+1-408-748-0100

Office Hours: 8:30am - 5:30pm PST