To create dispensing nozzles that can be used in confined spaces while keeping the same characteristics as ARQUE dispensing nozzles.

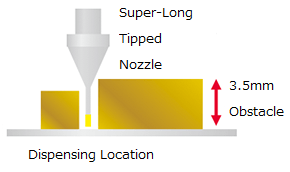

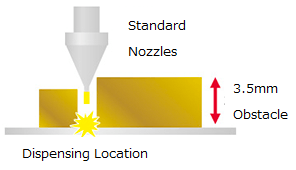

When developing dispensing nozzles for camera modules the main obstacle to overcome was the obstruction of the dispensing location by a component with a height of 3.5 mm. This component makes it impossible to accurately apply the fluid using the ARQUE dispensing nozzles.

Going beyond current manufacturing capabilities to create a super-long tipped nozzle.

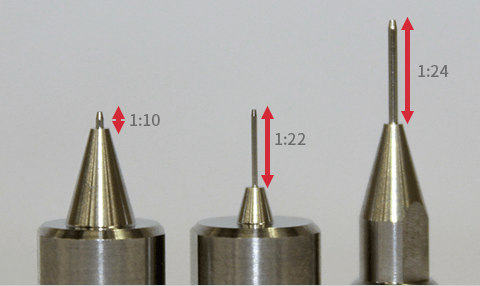

As a solution, it was necessary to make the nozzle tip 4.5 mm or more higher than the workpiece height. Assembled type needles and standard needles have internal steps that cause clogging due to material accumulation and hardening. A new dispenser nozzle with a longer tip was needed while maintaining the performance of the dispenser nozzle in order to achieve accurate and stable application to details as before. The current limits of manufacturing were believed to be 1:10 (inner diameter: tip length), however Tecdia has developed nozzles with aspect ratios up to 1:24 as shown below.

(Left): Arque dispensing nozzle

(middle): Φ0.2mm, tip length 4.5mm

(right): Φ0.25mm, tip length 6mm

Tecdia has achieved all of this while keeping the tapered interior design and by machining the nozzles from one piece of metal we are able to maintain the same performance as the ARQUE dispensing nozzles.

These features resolve clogging issues conventionally present during prototyping. In addition, the tip has been polished to eliminate problematic creep up and stretching of materials after dispensing, delivering the performance required by Tecdia customers.

Our products passed evaluation for mass manufacturing and are being used to dispense materials used for camera module production by multiple manufacturers.

[Client Industries]

Camera module manufacturers (China) / Electronic manufacturing service (Taiwan)

[Target Application]

Compact camera module manufacturing / Contract manufacturing of electronic components

+1-408-748-0100

+1-408-748-0100

Office Hours: 8:30am - 5:30pm PST