| MOQ | 1 piece |

| Material | SUS303 |

| Packaging | Individual Packaging |

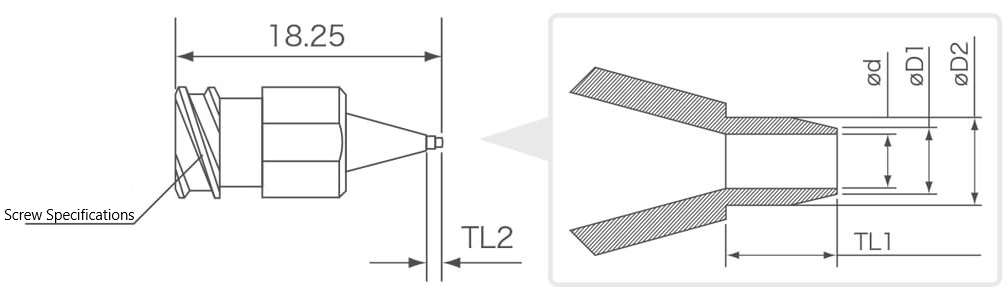

Unit:mm

| Customizable Items | Specification |

| Internal Tip Length (TL1) | 1)Please refer to spec table below 2)TL1 & TL2 have the same diameter as standard parts. |

| External Tip Length (TL2) | |

| Inner Diameter (φd) | φd ≧ 0.1 |

| Outer Diameter 1(φD1) | φD1 ≧ φd+0.05 |

| Outer Diameter 2(φD2) | φD2 ≧ φd+0.1、φD2 < φ1.0 |

| Screw Specifications | 2 thread screw, 1 thread screw, metal coarse screw. |

* Depending on the inner thickness of the tip, it may not be possible to manufacture with the above contents.

|

|

Tecdia offers customization for many of our products. If you wish to explore this option, please contact us at sales@tecdia.com.

|

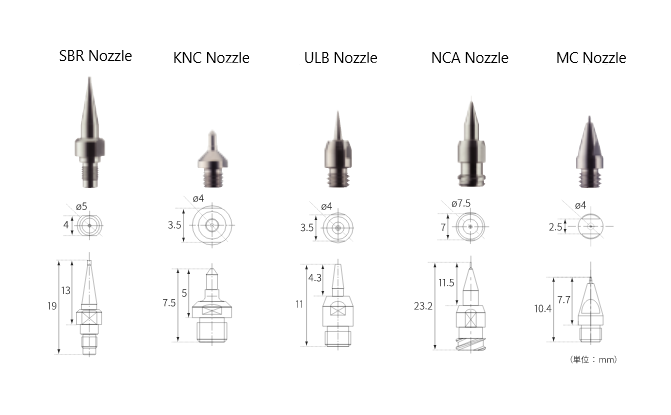

Multi-Shot Range Nozzle Reduces takt time incorporating two shots onto one.

|

|---|

|

Multi-Shot Range Nozzle Enables “drawing dispensing” with a cross pattern shape.

|

|---|

|

Nozzle for Low Viscosity / Low Pressure Dispensing Allows the dispensing of low viscosity materials with minimal dripping.

|

|

Nozzle for Dense Component Environments Used for hard to reach areas. Without altering the inner diameter,

|

|

Stamp Method Nozzle In traditional pin transfer method there is a need to repeatedly dip

|

|

High Fluidity Material Dispensing Nozzle Pipes are attached to the nozzle fixture by press and crimp methods vs. using adhesives.

|

In addition, we manufacture according to each company’s specifications.

Please contact us for details.

+1-408-748-0100

+1-408-748-0100

Office Hours: 8:30am - 5:30pm PST