Historically, improvement in tool precision and the production yield of nanoindentation tools has been a tremendous challenge.

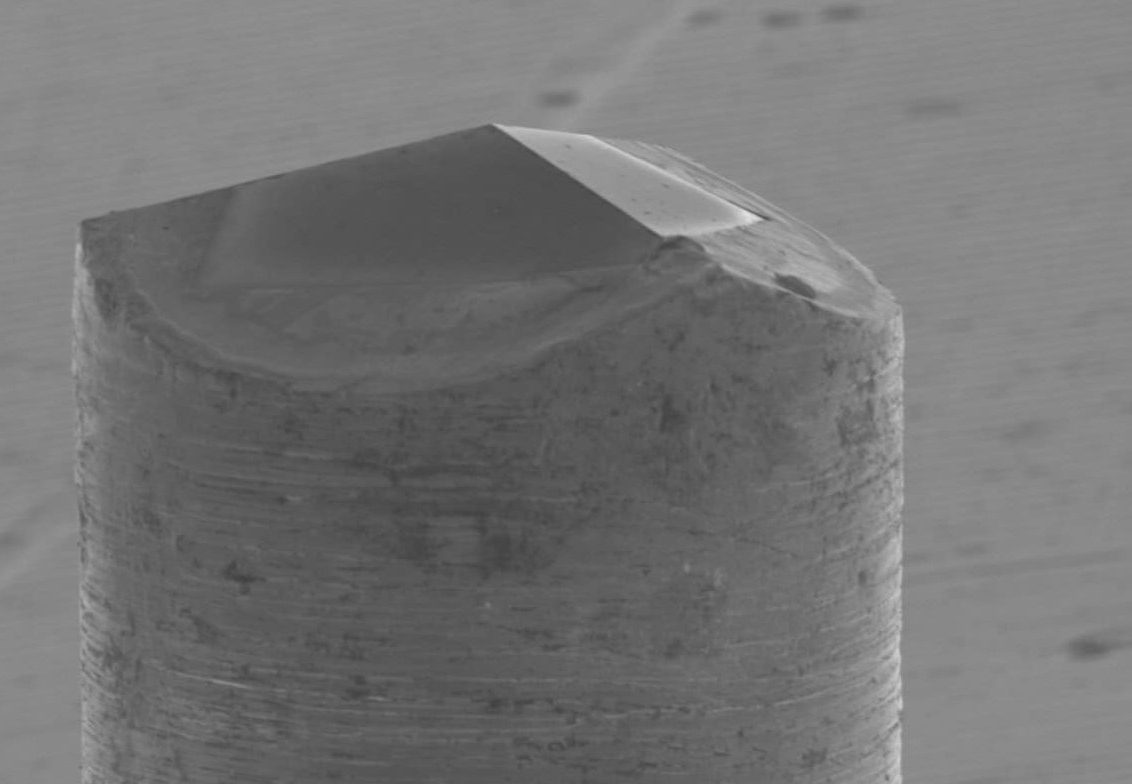

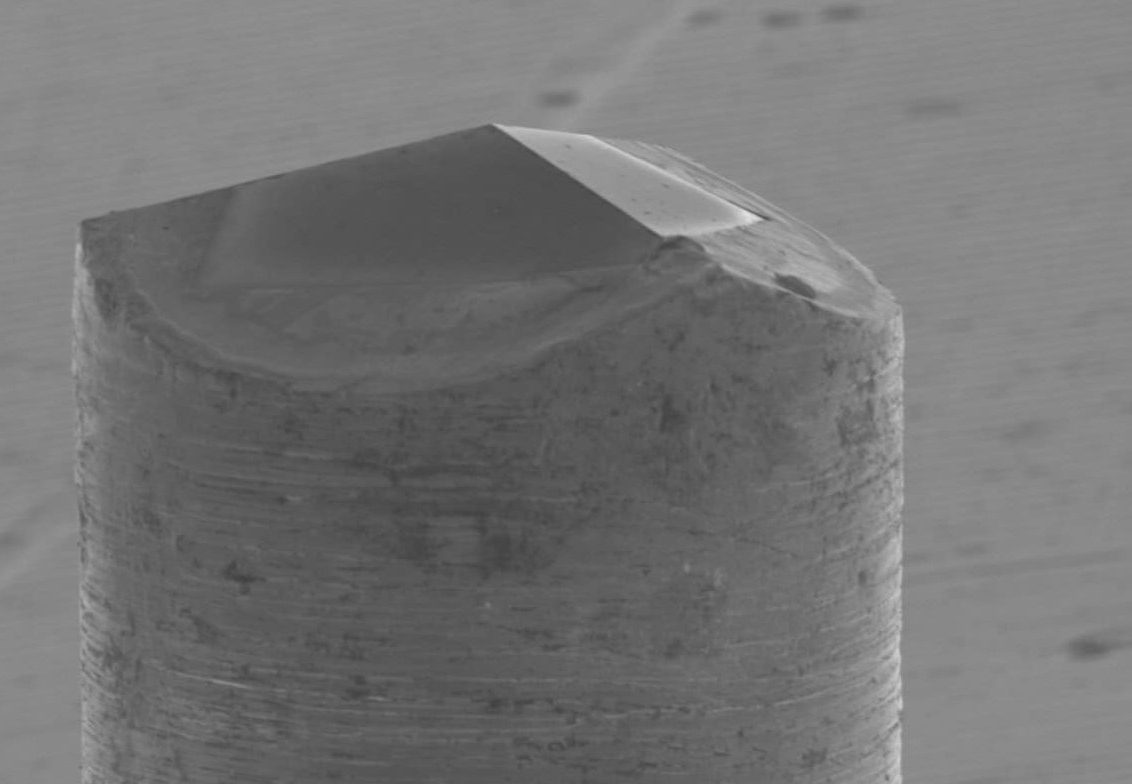

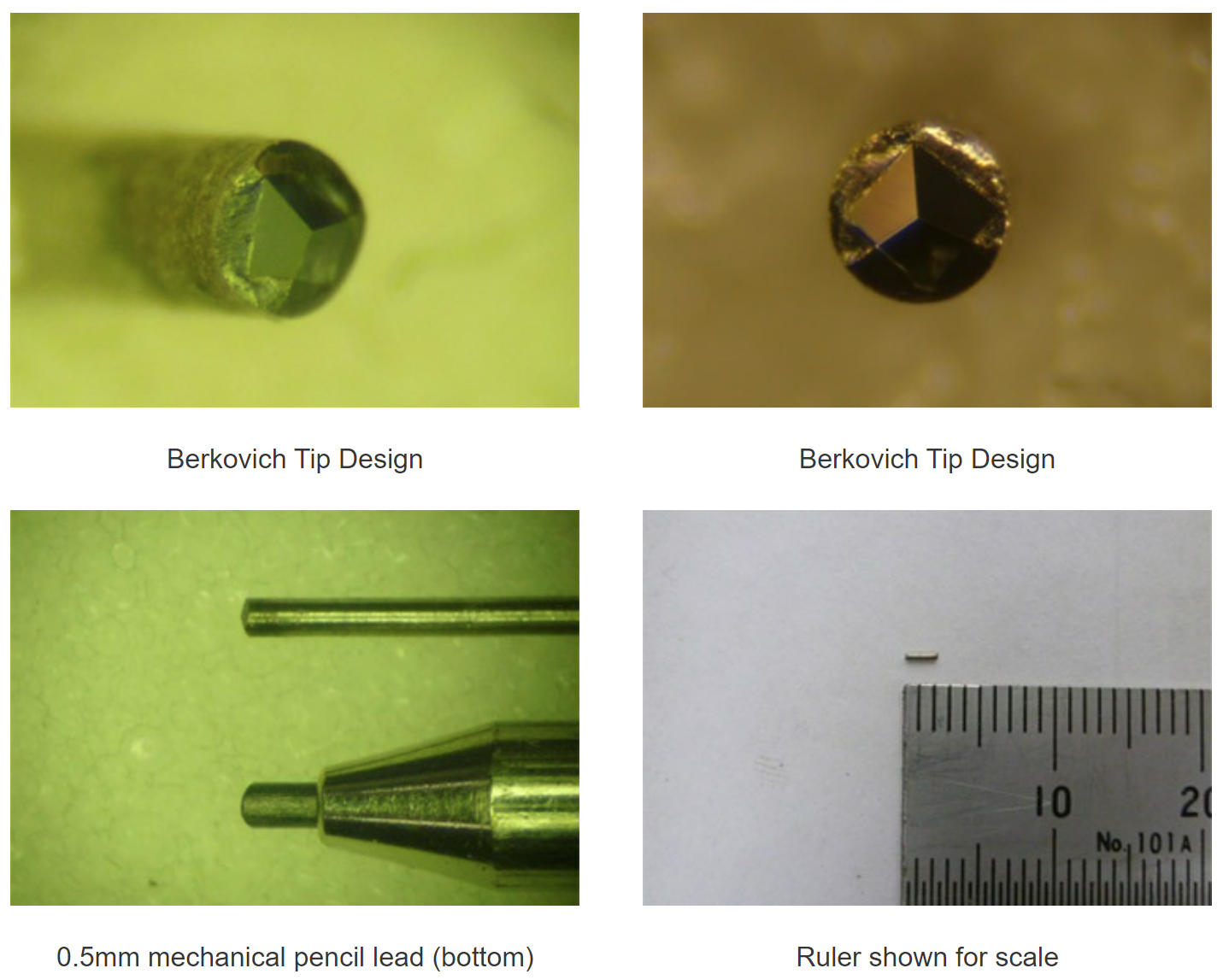

Nanoindenters consist of a diamond tip and Titanium or stainless steel shaft. The shaft diameter is typically less than 0.5mm and the total length is only 2 to 3mm long. The tip radius is less than 100 nanometers.

While diamond is the hardest material on Earth, they can be very brittle and difficult to work with at the microscopic level. Affixing the diamonds to the shaft with consistency and precision was also a challenge. Advancements in both shaping and mounting techniques were developed in order to attain consistent yields.

By combining our expertise in diamond processing and precision instrument production, Tecdia developed a need-based solution.

Not only were we able to exceed our customer’s expectations for precision, we were also able to increase the consistency of our product, in which high yields are crucial for continued satisfaction. Tecdia mobilized our expertise in mass production to provide a high-precision, best-in-class diamond Nanoindenter solution.

+1-408-748-0100

+1-408-748-0100

Office Hours: 8:30am - 5:30pm PST