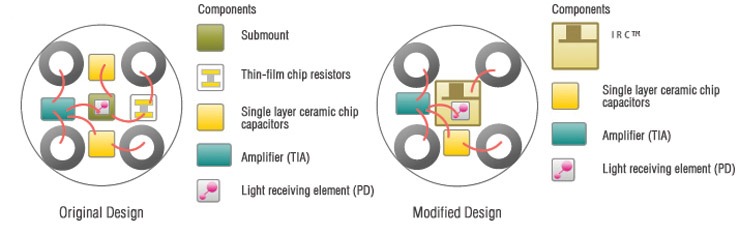

Photodiode devices, like a Receiver Optical Sub-Assembly (ROSA), used to detect light transmitted through fiber optical cables are typically compact in design. The basic components inside are a light sensor (PD and header) an amplifier (TIA), capacitor(s), and a resistor. The capacitor and resistor are used to protect and enhance the sensitivity of the photodiode by reducing electromagnetic noise.

The photodetectors designs may vary, but the market demands each design be smaller and cheaper than the last. Once Tecdia understood the OEMs’ roadblocks we divided their challenges into categories based on the form and function of the components, the circuit connections, and the installation process.

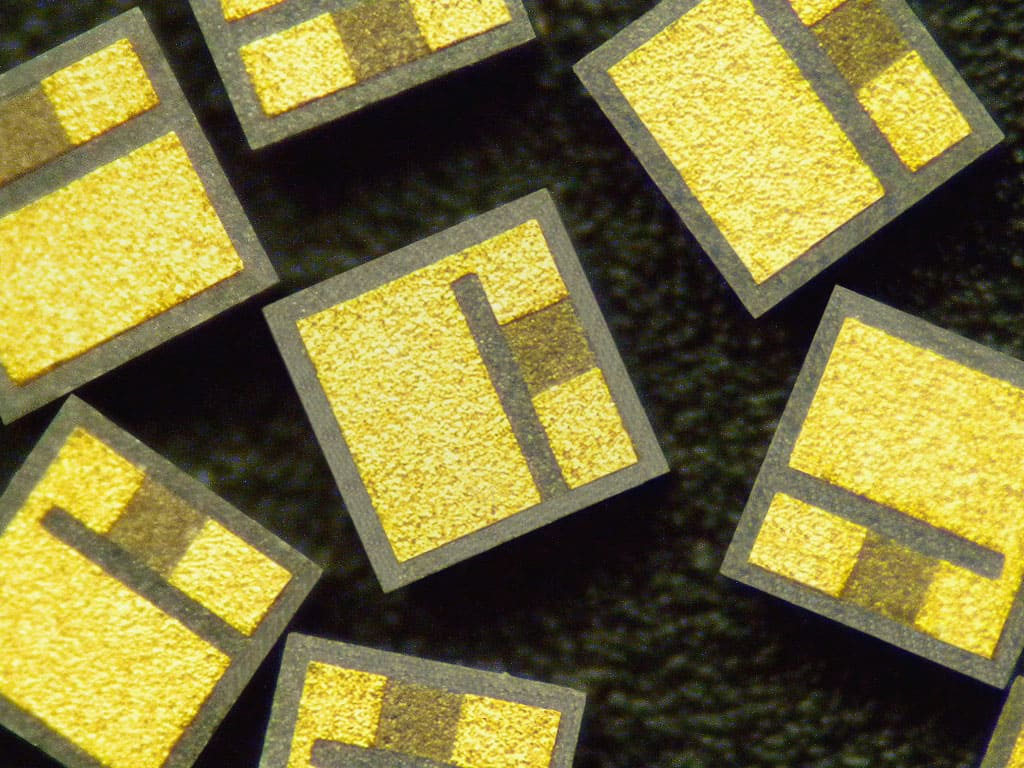

The challenge we faced was to integrate a parallel plate capacitor with a thin film resistor in a small easily wire bondable configuration metallized on the same ceramic chip face. Also an open space had to remain on that face for mounting a photodiode chip while still leaving the chip small enough to fit in the center of the device. Changes in the wire bond connections were made to compensate for the relocation of components. The end product from this venture was the three in one IRC (Integrated Resistor + Capacitor) on a ceramic chip that can also serve as a submount for the photodiode as shown below.

Utilize Tecdia’s “Thin Film” expertise to develop an all-in-one design.

Illustrated below are before and after circuit designs of a typical application. The circuit on the left without the IRC consists of six discrete components and four pin terminals linked by one or more wire bonds. On the right is a design that has the IRC mounted in the center and the photodiode mounted on the IRC. Thanks to our integrated thin film components the discrete components have been reduced from six to four, and the number of wire bonds from eight to six.

To achieve this new component we capitalized on Tecdia’s technical knowledge and experience in manufacturing single layer GBBL ceramic chip capacitors, thin-film chip resistors, and optical submounts. Tecdia is comprised of multiple business units that cover a wide variety of technologies and crafts, providing rich interdisciplinary resources for this task which is why we were able to develop this unique component.

* The design has a border on the top surface to eliminate the problem of shorts caused by creeping up epoxy.

The ability to apply thin film technology in the ceramic business since the founding of Tecdia.

We have already applied the product concept, which has already become commonplace in the microwave industry, to the optical business by further integrating and miniaturizing it.

In the optical communication industry, where there is an increasing demand for compact, high-capacity single-plate ceramic capacitors, Tecdia’s fusion technology with the single-plate ceramic capacitor “ALTAS®” has led to a solution.

The design of the photodiode device has a simplified layout with open spaces.

The production engineer has fewer components to install and connect. Inspection sees higher yields (reduced risk of electrical shorts from excess epoxy and installation errors). Purchasing and material departments have less stock to buy and manage. Marketing has a more robust product (fewer components and wire connections). Finally, the OEM has a lower cost and environmentally friendly product.

【Client Industries】

Manufacturing of optical device & module manufacturing such as ROSAs, BOSAs, Optical Transceivers

+1-408-748-0100

+1-408-748-0100

Office Hours: 8:30am - 5:30pm PST